Inflow-exhaust ventilation units with heat recovery (rotary recuperator) and built-in automation, up to 1000 m3 per hour.

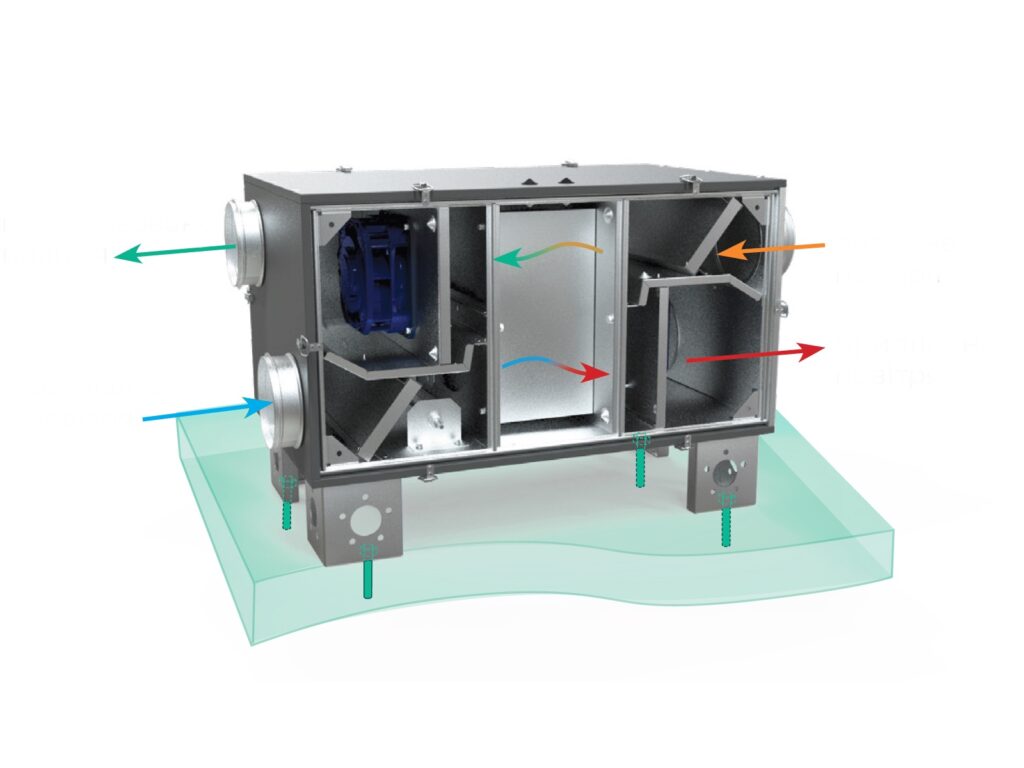

Ventilation unit EZ FRH – floor installation, horizontal, rotary

| Supply air flow | 500 m3/h | Нeat exchanger | Rotary |

| Extract air flow | 500 m3/h | Nominal power input | 2.3 kW |

| Air velocity in the supply section | 1.8 m/s | Duct connection | Ø 160 mm |

| Air velocity in the extract section | 1.8 m/s | Total weight + damper, electric heater | 85 + 1 +2 kg |

| Supply external static pressure | 150 Pa | Width | 562 mm |

| Extract external static pressure | 150 Pa | Length | 1000 mm |

| Design winter temperature | -22 °C | Height + legs | 485 + 85 mm |

| Heat recovery efficiency | 78.31 % |

| Supply air flow | 650 m3/h | Нeat exchanger | Rotary |

| Extract air flow | 650 m3/h | Nominal power input | 3.3 kW |

| Air velocity in the supply section | 1.35 m/s | Duct connection | Ø 250 mm |

| Air velocity in the extract section | 1.35 m/s | Total weight + damper, electric heater | 88 + 1 +1 kg |

| Supply external static pressure | 80 Pa | Width | 662 mm |

| Extract external static pressure | 80 Pa | Length | 1050 mm |

| Design winter temperature | -22 °C | Height + legs | 550 + 85 mm |

| Heat recovery efficiency | 74.22 % |

| Supply air flow | 1000 m3/h | Нeat exchanger | Rotary |

| Extract air flow | 1000 m3/h | Nominal power input | 7 kW |

| Air velocity in the supply section | 2.07 m/s | Duct connection | Ø 315 mm |

| Air velocity in the extract section | 2.07 m/s | Total weight + damper, electric heater | 121 + 1 +1 kg |

| Supply external static pressure | 150 Pa | Width | 800 mm |

| Extract external static pressure | 150 Pa | Length | 1200 mm |

| Design winter temperature | -22 °C | Height + legs | 620 + 85 mm |

| Heat recovery efficiency | 78.55 % |

The installation is an energy-efficient inflow-exhaust system with a rotary recuperator, capable of processing up to 1000 m³/h of air.

It is designed for small spaces such as daycare centers, offices, banks, restaurants, shops, and others, where energy savings are crucial due to low power consumption.

All units come with built-in automation. Controllers and all control elements are configured and ready for operation:

- Monitoring equipment operation parameters, automatic restart.

- Smooth regulation, maintaining the temperature of the incoming air.

- Receiving signals about filter contamination, emergency alarms.

- Control of dampers with servo drives and other available options.

Detailed Equipment Specifications PDF File: