Inflow-exhaust ventilation units with heat recovery (plate heat exchanger) and built-in automation, up to 2400 m3 per hour.

Ventilation unit EZ SPH – ceiling installation

| Supply air flow | 1500 m3/h | Нeat exchanger | Plate |

| Extract air flow | 1500 m3/h | Nominal power input | 9.2 kW |

| Air velocity in the supply section | 1.74 m/s | Duct connection | Ø 500×300 mm |

| Air velocity in the extract section | 1.74 m/s | Total weight + damper, electric heater | 157 + 12 +10 kg |

| Supply external static pressure | 150 Pa | Width | 1445 mm |

| Extract external static pressure | 150 Pa | Length | 1700 mm |

| Design winter temperature | -22 °C | Height | 500 mm |

| Heat recovery efficiency | 78.9 % |

| Supply air flow | 2000 m3/h | Нeat exchanger | Plate |

| Extract air flow | 2000 m3/h | Nominal power input | 13.2 kW |

| Air velocity in the supply section | 1.74 m/s | Duct connection | Ø 600×300 mm |

| Air velocity in the extract section | 1.74 m/s | Total weight + damper, electric heater | 169 + 13 +3 kg |

| Supply external static pressure | 150 Pa | Width | 1845 mm |

| Extract external static pressure | 150 Pa | Length | 1700 mm |

| Design winter temperature | -22 °C | Height | 500 mm |

| Heat recovery efficiency | 78.9 % |

| Supply air flow | 2500 m3/h | Нeat exchanger | Plate |

| Extract air flow | 2500 m3/h | Nominal power input | 16.2 kW |

| Air velocity in the supply section | 1.88 m/s | Duct connection | Ø 600×300 mm |

| Air velocity in the extract section | 1.88 m/s | Total weight + damper, electric heater | 254 + 13 +3 kg |

| Supply external static pressure | 150 Pa | Width | 1745 mm |

| Extract external static pressure | 150 Pa | Length | 1600 mm |

| Design winter temperature | -22 °C | Height + legs | 500 mm |

| Heat recovery efficiency | 78.7 % |

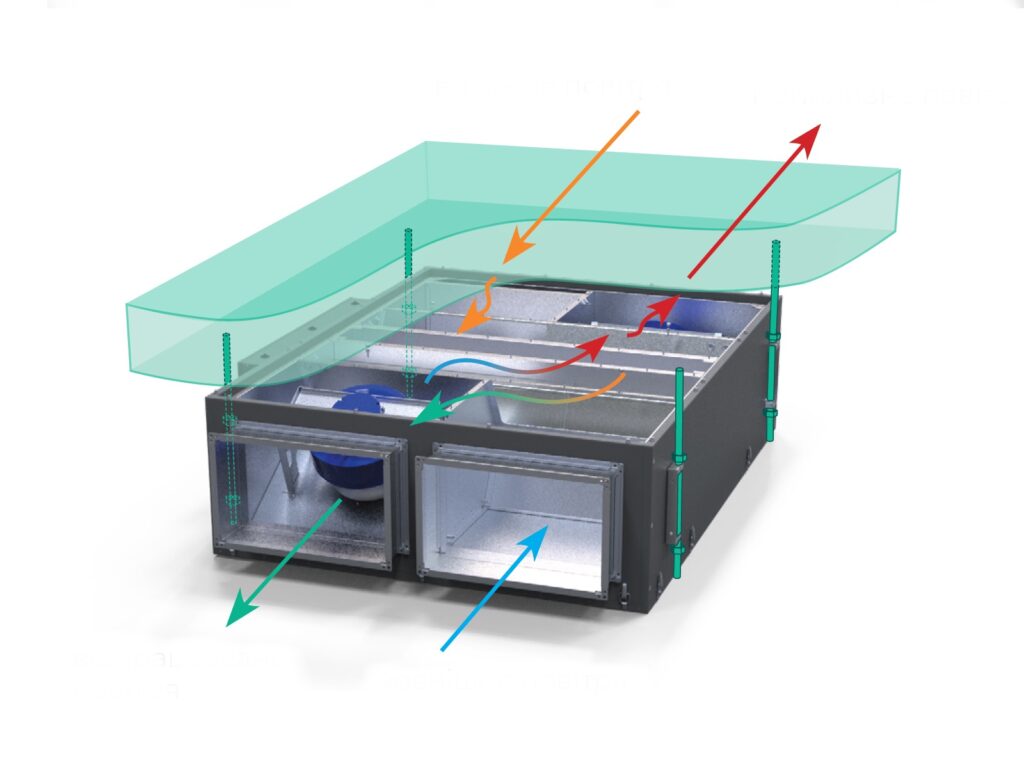

The installation is a ceiling-mounted, compact, and multifunctional unit with an inflow-exhaust system and a plate-type recuperator.

Its productivity reaches up to 2400 m³/h.

It is applicable in various types of spaces such as private houses, apartments, restaurants, salons, workshops, schools, administrative buildings, and even in “clean” rooms with high air quality requirements.

All units come with built-in automation. Controllers and all control elements are configured and ready for operation:

Monitoring equipment operation parameters, automatic restart.

Smooth regulation, maintaining the temperature of the incoming air.

Receiving signals about filter contamination, emergency alarms.

Control of dampers with servo drives and other available options.

Detailed Equipment Specifications PDF File: